Insul-Tek® Enviro-Tek Containment Piping

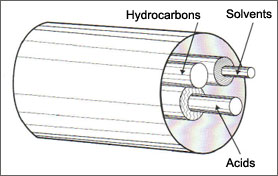

Preinsulated Piping Systems, Inc. offers a wide range of prefabricated and pre-engineered ENVIRO-TEK containment piping systems. Each system is custom designed and engineered to meet the specific requirements of the customer.

The carrier pipe can be of any grade and type commercially available, including, but not limited to: PVC, CPVC, fiberglass, steel, stainless steel, copper, polypropylene, and HDPE.

The standard containment casings are PVC, FRP, and Urethane-coated steel; however, other optional casings are available, including HDPE, Epoxy-coated steel, and stainless steel. We offer multiple pipe systems, insulated systems, heat traced systems, and systems with leak detection.

Please consult your local area representative or our engineering staff for additional assistance in designing your containment system.

Interior Fuel Oil

MATERIAL:

All pipe shall be factory fabricated Enviro-Tek Containment pipe as manufactured by Insul-Tek® Piping Systems, Inc. No field fabricated piping will be allowed.

CARRIER PIPE:

Schedule 40 or Schedule 80 ASTM A53 Grade B beveled for welding or other as specified.

SPACERS:

Minimum 'A" thick steel located no more than 10 feet apart within outer conduit casing fabricated in such a manner to allow complete draining of the conduit system ff a carrier pipe leak occurs.

OUTER CASING:

Welded smooth wall steel of not less than 10 gauge in wall thickness, with a coat of grey or red oxide primer.

FITTINGS:

Prefabricated of the same construction as the straight lengths of pipe.

FIELD JOINTS:

Field joints shall consist of a rolled 10 gauge steel sleeve with it welded into place.

TESTING:

The carrier pipe shall be hydrostatically pressure tested to a pressure of 1.5 times the working pressure of the piping system. The outer casing shall be air tested to 15 psig after completion of all of the field joints.